SECTION 1. IDENTIFICATION

Product Name: Sodium Dithionite

Product Number: All applicable American Elements product codes, e.g. NA-DTH-01-P

CAS #: 7775-14-6

Relevant identified uses of the substance: Scientific research and development

Supplier details:

American Elements

10884 Weyburn Ave.

Los Angeles, CA 90024

Tel: +1 310-208-0551

Fax: +1 310-208-0351

Emergency telephone number:

Domestic, North America: +1 800-424-9300

International: +1 703-527-3887

SECTION 2. HAZARDS IDENTIFICATION

2.1 Classification of the substance or mixture

GHS Classification in accordance with 29 CFR 1910 (OSHA HCS)

Self-heating substances and mixtures (Category 1), H251

Acute toxicity, Oral (Category 4), H302

Acute aquatic toxicity (Category 2), H401

Chronic aquatic toxicity (Category 2), H411

2.2 GHS Label elements, including precautionary statements

Pictogram

Signal word Danger

Hazard statement(s)

H251 Self-heating: may catch fire.

H302 Harmful if swallowed.

H411 Toxic to aquatic life with long lasting effects.

Precautionary statement(s)

P235 + P410 Keep cool. Protect from sunlight.

P264 Wash skin thoroughly after handling.

P270 Do not eat, drink or smoke when using this product.

P273 Avoid release to the environment.

P280 Wear protective gloves/ protective clothing/ eye protection/ face

protection.

P301 + P312 IF SWALLOWED: Call a POISON CENTER or doctor/ physician if you

feel unwell.

P330 Rinse mouth.

P391 Collect spillage.

P407 Maintain air gap between stacks/ pallets.

P410 Protect from sunlight.

P420 Store away from other materials.

P501 Dispose of contents/ container to an approved waste disposal plant.

2.3 Hazards not otherwise classified (HNOC) or not covered by GHS

Contact with acids liberates toxic gas.

SECTION 3. COMPOSITION/INFORMATION ON INGREDIENTS

3.1 Substances

Synonyms : Sodium dithionite

Sodium hypodisulfite

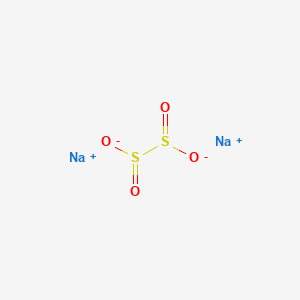

Formula : Na2O4S2

Molecular weight : 174.11 g/mol

CAS-No. : 7775-14-6

EC-No. : 231-890-0

Index-No. : 016-028-00-1

Hazardous components

Component Classification Concentration

Sodium dithionite

Self-heat. 1; Acute Tox. 4;

Aquatic Acute 2; Aquatic

Chronic 2; H251, H302, H411

90 - 100 %

SECTION 4. FIRST AID MEASURES

4.1 Description of first aid measures

General advice

Consult a physician. Show this safety data sheet to the doctor in attendance.Move out of dangerous area.

If inhaled

If breathed in, move person into fresh air. If not breathing, give artificial respiration. Consult a physician.

In case of skin contact

Wash off with soap and plenty of water. Consult a physician.

In case of eye contact

Flush eyes with water as a precaution.

If swallowed

Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician.

4.2 Most important symptoms and effects, both acute and delayed

The most important known symptoms and effects are described in the labelling (see section 2.2) and/or in section 11

4.3 Indication of any immediate medical attention and special treatment needed

No data available

SECTION 5. FIREFIGHTING MEASURES

5.1 Extinguishing media

Suitable extinguishing media

Dry powder

5.2 Special hazards arising from the substance or mixture

Sulphur oxides, Sodium oxides

5.3 Advice for firefighters

Wear self-contained breathing apparatus for firefighting if necessary.

5.4 Further information

Addition of small amounts of water may cause self ignition.

SECTION 6. ACCIDENTAL RELEASE MEASURES

6.1 Personal precautions, protective equipment and emergency procedures

Wear respiratory protection. Avoid dust formation. Avoid breathing Vapors, mist or gas. Ensure adequate ventilation.

Evacuate personnel to safe areas. Avoid breathing dust.

For personal protection see section 8.

6.2 Environmental precautions

Prevent further leakage or spillage if safe to do so. Do not let product enter drains. Discharge into the environment

must be avoided.

6.3 Methods and materials for containment and cleaning up

Sweep up and shovel. Contain spillage, and then collect with an electrically protected vacuum cleaner or by wetbrushing

and place in container for disposal according to local regulations (see section 13). Do not flush with water.

Keep in suitable, closed containers for disposal.

6.4 Reference to other sections

For disposal see section 13.

SECTION 7. HANDLING AND STORAGE

7.1 Precautions for safe handling

Avoid contact with skin and eyes. Avoid formation of dust and aerosols.Further processing of solid materials may result

in the formation of combustible dusts. The potential for combustible dust formation should be taken into consideration

before additional processing occurs.

Provide appropriate exhaust ventilation at places where dust is formed.Keep away from sources of ignition - No

smoking.

For precautions see section 2.2.

7.2 Conditions for safe storage, including any incompatibilities

Keep container tightly closed in a dry and well-ventilated place.

Never allow product to get in contact with water during storage. Do not store near acids.

Keep in a dry place. Air-, heat-, and moisture-sensitive. Handle and store under inert gas. Keep in a dry place.

7.3 Specific end use(s)

Apart from the uses mentioned in section 1.2 no other specific uses are stipulated

SECTION 8. EXPOSURE CONTROLS/PERSONAL PROTECTION

8.1 Control parameters

Components with workplace control parameters

Contains no substances with occupational exposure limit values.

8.2 Exposure controls

Appropriate engineering controls

Handle in accordance with good industrial hygiene and safety practice. Wash hands before breaks and at the end of

workday.

Personal protective equipment

Eye/face protection

Face shield and safety glasses Use equipment for eye protection tested and approved under appropriate

government standards such as NIOSH (US) or EN 166(EU).

Skin protection

Handle with gloves. Gloves must be inspected prior to use. Use proper glove removal technique (without

touching glove's outer surface) to avoid skin contact with this product. Dispose of contaminated gloves after

use in accordance with applicable laws and good laboratory practices. Wash and dry hands.

Full contact

Material: Nitrile rubber

Minimum layer thickness: 0.11 mm

Break through time: > 480 min

Material tested:

Splash contact

Material: Nitrile rubber

Minimum layer thickness: 0.11 mm

Break through time: > 480 min

Material tested:

data source: KCL GmbH, D-36124 Eichenzell, phone +49 (0)6659 87300, e-mail sales@kcl.de, test method:

EN374

If used in solution, or mixed with other substances, and under conditions which differ from EN 374, contact the

supplier of the CE approved gloves. This recommendation is advisory only and must be evaluated by an

industrial hygienist and safety officer familiar with the specific situation of anticipated use by our customers. It

should not be construed as offering an approval for any specific use scenario.

Body Protection

Complete suit protecting against chemicals, The type of protective equipment must be selected according to

the concentration and amount of the dangerous substance at the specific workplace.

Respiratory protection

Where risk assessment shows air-purifying respirators are appropriate use a full-face particle respirator type

N100 (US) or type P3 (EN 143) respirator cartridges as a backup to engineering controls. If the respirator is the

sole means of protection, use a full-face supplied air respirator. Use respirators and components tested and

approved under appropriate government standards such as NIOSH (US) or CEN (EU).

Control of environmental exposure

Prevent further leakage or spillage if safe to do so. Do not let product enter drains. Discharge into the

environment must be avoided.

SECTION 9. PHYSICAL AND CHEMICAL PROPERTIES

9.1 Information on basic physical and chemical properties

a) Appearance Form: powder

Colour: white

b) Odor No data available

c) Odor Threshold No data available

d) pH 7.0 - 9 at 50 g/l at 20 °C (68 °F)

e) Melting point/freezing point 300 °C (572 °F)

f) Initial boiling point and boiling range No data available

g) Flash point No data available

h) Evaporation rate No data available

i) Flammability (solid, gas) No data available

j) Upper/lower flammability or explosive limits No data available

k) Vapor pressure No data available

l) Vapor density No data available

m) Relative density 2.500 g/cm3 at 20 °C (68 °F)

n) Water solubility No data available

o) Partition coefficient: noctanol/water log Pow: < -4.7

p) Auto-ignition temperature The substance or mixture is classified as self heating with the category 1.

q) Decomposition temperature No data available

r) Viscosity No data available

s) Explosive properties No data available

t) Oxidizing properties No data available

9.2 Other safety information Bulk density 1,250 kg/m3

SECTION 10. STABILITY AND REACTIVITY

10.1 Reactivity

No data available

10.2 Chemical stability

May decompose on exposure to air and moisture.

Stable under recommended storage conditions.

10.3 Possibility of hazardous reactions

No data available

10.4 Conditions to avoid

Do not allow water to enter container because of violent reaction. Avoid moisture. Heat.

10.5 Incompatible materials

Strong oxidizing agents, acids, Water

10.6 Hazardous decomposition products

Other decomposition products - No data available

In the event of fire: see section 5

SECTION 11. TOXICOLOGICAL INFORMATION

11.1 Information on toxicological effects

Acute toxicity

No data available

Inhalation: No data available

Dermal: No data available

No data available

Skin corrosion/irritation

No data available

Serious eye damage/eye irritation

No data available

Respiratory or skin sensitisation

No data available

Germ cell mutagenicity

No data available

Carcinogenicity

IARC: No component of this product present at levels greater than or equal to 0.1% is identified as

ACGIH: No component of this product present at levels greater than or equal to 0.1% is identified as a

carcinogen or potential carcinogen by ACGIH.

NTP: No component of this product present at levels greater than or equal to 0.1% is identified as a

known or anticipated carcinogen by NTP.

OSHA: No component of this product present at levels greater than or equal to 0.1% is identified as a

carcinogen or potential carcinogen by OSHA.

Reproductive toxicity

No data available

No data available

Specific target organ toxicity - single exposure

No data available

Specific target organ toxicity - repeated exposure

No data available

Aspiration hazard

No data available

Additional Information

RTECS: Not available

To the best of our knowledge, the chemical, physical, and toxicological properties have not been thoroughly

investigated.

SECTION 12. ECOLOGICAL INFORMATION

12.1 Toxicity

Toxicity to fish LC50 - Leuciscus idus (Golden orfe) - 10 - 100 mg/l - 96 h

Toxicity to daphnia and

other aquatic

invertebrates

EC50 - Daphnia magna (Water flea) - 10 - 100 mg/l - 48 h

12.2 Persistence and degradability

No data available

12.3 Bioaccumulative potential

No data available

12.4 Mobility in soil

No data available

12.5 Results of PBT and vPvB assessment

PBT/vPvB assessment not available as chemical safety assessment not required/not conducted

12.6 Other adverse effects

An environmental hazard cannot be excluded in the event of unprofessional handling or disposal.

Toxic to aquatic life.

No data available

SECTION 13. DISPOSAL CONSIDERATIONS

13.1 Waste treatment methods

Product

Burn in a chemical incinerator equipped with an afterburner and scrubber but exert extra care in igniting as this

material is highly flammable. Offer surplus and non-recyclable solutions to a licensed disposal company. Contact a

licensed professional waste disposal service to dispose of this material.

Contaminated packaging

Dispose of as unused product.

SECTION 14. TRANSPORT INFORMATION

DOT (US)

UN number: 1384 Class: 4.2 Packing group: II

Proper shipping name: Sodium dithionite

Reportable Quantity (RQ):

Marine pollutant: No

Poison Inhalation Hazard: No

IMDG

UN number: 1384 Class: 4.2 Packing group: II EMS-No: F-A, S-J

Proper shipping name: SODIUM DITHIONITE

Marine pollutant: No

IATA

UN number: 1384 Class: 4.2 Packing group: II

Proper shipping name: Sodium dithionite

SECTION 15. REGULATORY INFORMATION

SARA 302 Components

No chemicals in this material are subject to the reporting requirements of SARA Title III, Section 302.

SARA 313 Components

This material does not contain any chemical components with known CAS numbers that exceed the threshold (De

Minimis) reporting levels established by SARA Title III, Section 313.

SARA 311/312 Hazards

Reactivity Hazard, Acute Health Hazard

Massachusetts Right To Know Components

Sodium dithionite

CAS-No.

7775-14-6

Revision Date

1993-04-24

Pennsylvania Right To Know Components

Sodium dithionite

CAS-No.

7775-14-6

Revision Date

1993-04-24

New Jersey Right To Know Components

Sodium dithionite

CAS-No.

7775-14-6

Revision Date

1993-04-24

California Prop. 65 Components

This product does not contain any chemicals known to State of California to cause cancer, birth defects, or any other

reproductive harm.

SECTION 16. OTHER INFORMATION

Safety Data Sheet according to Regulation (EC) No. 1907/2006 (REACH). The above information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide. The information in this document is based on the present state of our knowledge and is applicable to the product with regard to appropriate safety precautions. It does not represent any guarantee of the properties of the product. American Elements shall not be held liable for any damage resulting from handling or from contact with the above product. See reverse side of invoice or packing slip for additional terms and conditions of sale. COPYRIGHT 1997-2022 AMERICAN ELEMENTS. LICENSED GRANTED TO MAKE UNLIMITED PAPER COPIES FOR INTERNAL USE ONLY.

See more Sodium products.

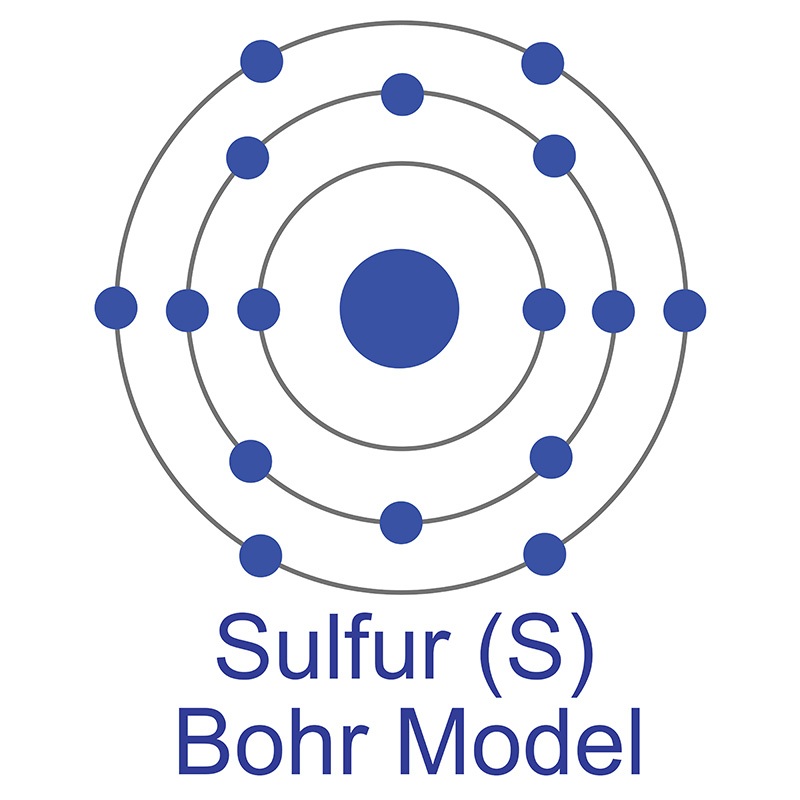

See more Sodium products. The number of electrons in each of Sulfur's shells is 2, 8, 6 and its electron configuration is [Ne] 3s2 3p4. In its elemental form, sulfur has a light yellow appearance. The sulfur atom has a covalent radius of 105 pm and a Van der Waals radius of 180 pm. In nature, sulfur can be found in hot springs, meteorites, volcanoes, and as galena, gypsum, and epsom salts. Sulfur has been known since ancient times but was not accepted as an element until 1777, when Antoine Lavoisier helped to convince the scientific community that it was an element and not a compound.

The number of electrons in each of Sulfur's shells is 2, 8, 6 and its electron configuration is [Ne] 3s2 3p4. In its elemental form, sulfur has a light yellow appearance. The sulfur atom has a covalent radius of 105 pm and a Van der Waals radius of 180 pm. In nature, sulfur can be found in hot springs, meteorites, volcanoes, and as galena, gypsum, and epsom salts. Sulfur has been known since ancient times but was not accepted as an element until 1777, when Antoine Lavoisier helped to convince the scientific community that it was an element and not a compound.