About Magnesium

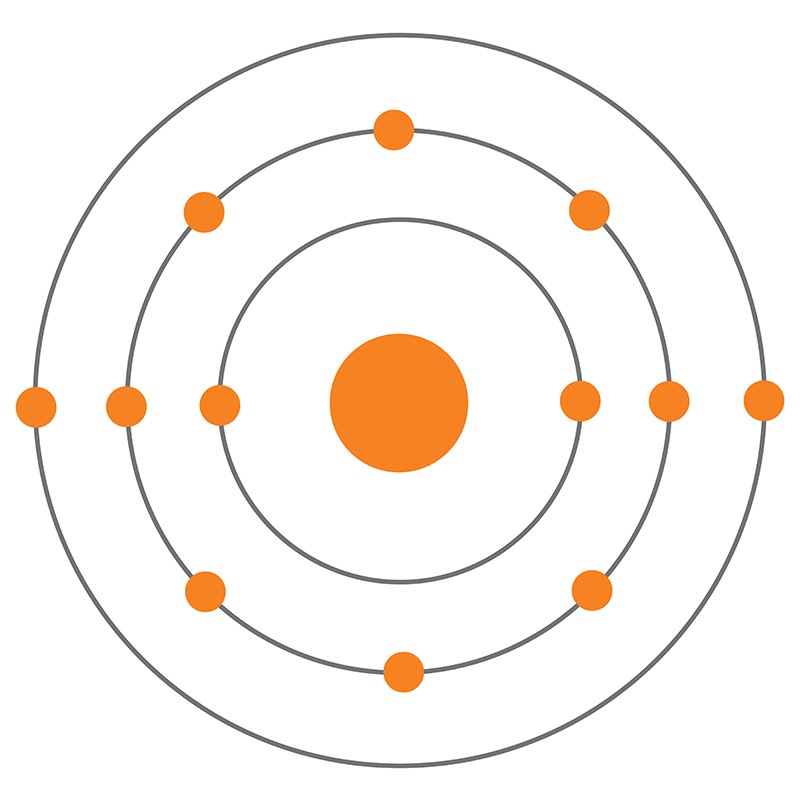

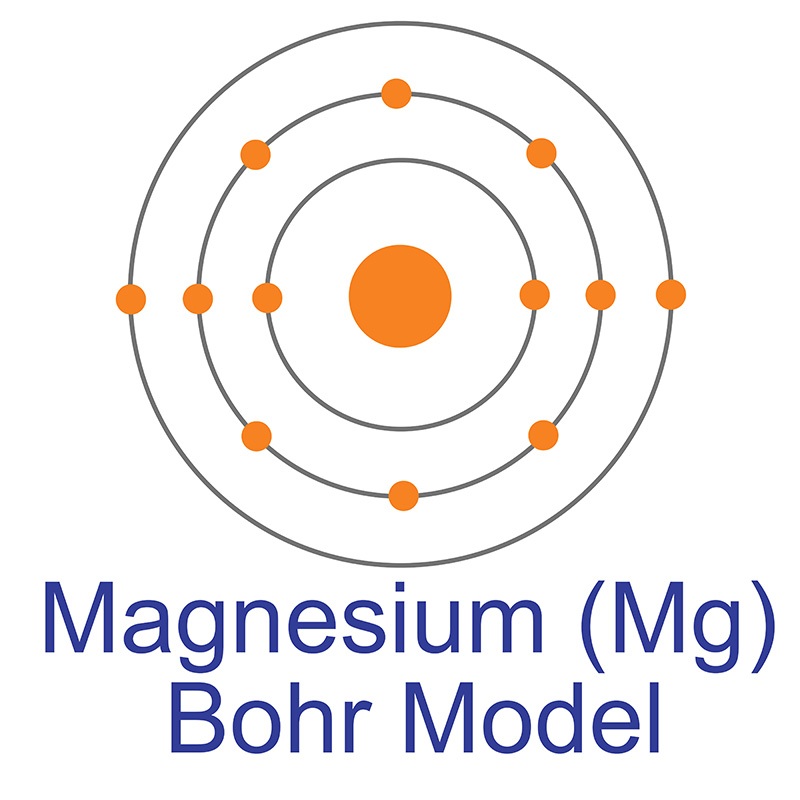

Magnesium is a shiny, silvery-white alkaline earth element that is widely considered to be the lightest structural metal for industrial applications. The two metals that precede it on the periodic table, though less dense, are unsuited to all-purpose applications due to toxicity, in the case of beryllium, or dangerous reactivity, in the case of lithium. This light but useful metal was first isolated by Sir Humphry Davy in 1808 via electrolysis of its oxide.

Magnesium’s density of 1.7 g/ g/cm3 is two-thirds that of aluminum and one-fifth that of iron; its density, paired with its excellent vibrational-damping properties and its high specific heat (the fourth highest of all metals), makes it especially important as an alloying agent that can decrease weight without significantly compromising strength or rigidity. Lightweight magnesium alloys are critical for structural components in a wide range of industries, including aerospace and defense (in satellite, aircraft, and missile design), automotive (engine casings and external panels that can boost fuel efficiency by decreasing overall weight of the vehicle), sports equipment (golf clubs and bicycles), consumer goods (high-end appliances, beverage cans). Adding magnesium, a highly malleable metal, to aluminum greatly improves its machinability; magnesium-aluminum-zinc alloys are some of the most commonly employed commercial alloys and can be produced in a number of different forms, including extrusions, forgings, rolled sheets or plates, and castings (sand, permanent-mold, and, most commonly, die castings). Other common alloying agents include zirconium, manganese, rare earth metals, and thorium, the latter two which have been shown to improve the creep resistance and strength of magnesium alloys in high temperature environments.

The chemical properties of magnesium are also useful for numerous non-structural metallurgical applications such as the serving as an additive during the production of nodular graphite (ductile) cast iron, as a reducing agent in the production of other metals such as uranium, titanium or hafnium, and as a desulfurizing agent in the production of steel. Researchers devote much attention to studying the properties and potential applications for magnesium metal on an ongoing basis; more recent developments include the production of extremely lightweight lithium-magnesium alloys for aerospace applications with densities as low as 1.14 g/cm3 and finding that adding arsenic to magnesium greatly reduces the metal’s susceptibility to corrosion.

Magnesium compounds are also of importance in modern industry. Magnesium reagents play essential roles in synthetic chemistry—magnesium molybdate is used as a catalyst in condensation, reduction, addition, and dehalogenation reactions, while magnesium-containing organometallic compounds called Grignard reagents are an essential tool used in the formation of carbon-carbon bonds. A variety of magnesium compounds are used as fertilizer additives or water treatment agents, and magnesium chloride is frequently used for dust and ice control in construction industries. In the production of electronics products, magnesium is an important dopant of semiconducting crystalline materials, and the metal has been considered as a potential replacement for plastic in some components of handheld electronics such as cell phones.

Finally, a variety of magnesium compounds increasingly play a role in environmental preservation efforts. Natural minerals composed of magnesium silicates and ammonium salt can be used to capture carbon from the atmosphere, making them a candidate for inexpensive carbon sequestration. Magnesium-based metal-organic-frameworks (MOFs) are under investigation for use as molecular sieves to remove toxins from contaminated water, and pure magnesium is of interest for hydrogen storage applications, as its hydride is stable and can be easily stored to hold energy for long periods.

Despite its ubiquity to the average consumer, magnesium metal is in fact highly flammable, particularly in powdered form, and requires special health and safety guidelines. Fine particles or strips of magnesium ignite violently when exposed to air (a property that is utilized in pyrotechnics and flash bulbs), burning in atmospheres of both oxygen and carbon dioxide and cannot be extinguished with water; rather, adding water to a magnesium flame produces hydrogen gas as a byproduct that poses an explosion risk. The bright white flame radiates in the ultraviolet range, requiring special UV-blocking eye goggles to prevent damage to the retinas. Beyond these risks, however, magnesium is not only non-toxic, but the magnesium ion (Mg2+) is essential to the proper functioning of all living cell systems and is the fourth most common cation present in the human body. Compounds of magnesium are some of the most common ingredients found in dietary supplements, pharmaceuticals, laxatives, and antacids such as milk of magnesia (an aqueous solution of magnesium hydroxide). Hydrated magnesium sulfate is better known as Epsom salts, a well-known over-the-counter remedy for soothing skin rashes.

Magnesium is the eighth most abundant element in the earth’s crust and the second most abundant metal dissolved in seawater. Though it does not occur naturally by itself, it can also be found in minerals such as brucite, carnallite, dolomite, magnesite, olivine, talc, dolomite, and magnesite. Magnesium can be obtained either from seawater-derived brines using electrolysis, or extracted from minerals using a silicothermic reaction. The latter method of production is of considerable importance in modern industry, and is especially prevalent in China.

Products

Magnesium is one-third lighter than aluminum and it improves the mechanical, fabrication, and welding characteristics of aluminum when used as an alloying agent.

Magnesium is one-third lighter than aluminum and it improves the mechanical, fabrication, and welding characteristics of aluminum when used as an alloying agent. It is used for aerospace, satellite and missile construction. Magnesium compounds, primarily magnesium oxide, are used as refractory material in furnace linings for producing iron and steel, nonferrous metals, glass, and cement. High purity magnesium is found in dietary supplements. Magnesium is available as metal and compounds with purities from 99% to 99.999% (ACS grade to ultra-high purity). Elemental or metallic forms include pellets, rod, wire and granules for evaporation source material purposes. Magnesium oxide is available in powder and dense pellet form for such uses as optical coating and thin film applications. Oxides tend to be insoluble. Magnesium fluoride is another insoluble form for uses in which oxygen is undesirable such as metallurgy, chemical and physical vapor deposition and in some optical coatings. Magnesium is also available in soluble forms including magnesium chloride, magnesium nitrate, and magnesium acetate. These compounds can be manufactured as solutions at specified stoichiometries.

It is used for aerospace, satellite and missile construction. Magnesium compounds, primarily magnesium oxide, are used as refractory material in furnace linings for producing iron and steel, nonferrous metals, glass, and cement. High purity magnesium is found in dietary supplements. Magnesium is available as metal and compounds with purities from 99% to 99.999% (ACS grade to ultra-high purity). Elemental or metallic forms include pellets, rod, wire and granules for evaporation source material purposes. Magnesium oxide is available in powder and dense pellet form for such uses as optical coating and thin film applications. Oxides tend to be insoluble. Magnesium fluoride is another insoluble form for uses in which oxygen is undesirable such as metallurgy, chemical and physical vapor deposition and in some optical coatings. Magnesium is also available in soluble forms including magnesium chloride, magnesium nitrate, and magnesium acetate. These compounds can be manufactured as solutions at specified stoichiometries.

Magnesium Properties

Magnesium is the eighth most abundant element in the earth's crust. It is commercially produced from brucite, carnallite, dolomite, magnesite, olivine and talc. Magnesium was discovered by Joseph Black in 1775 and first isolated by Sir Humphry Davy in 1808. The name Magnesium originates from a Greek district in Thessaly called Magnesia.

Magnesium is the eighth most abundant element in the earth's crust. It is commercially produced from brucite, carnallite, dolomite, magnesite, olivine and talc. Magnesium was discovered by Joseph Black in 1775 and first isolated by Sir Humphry Davy in 1808. The name Magnesium originates from a Greek district in Thessaly called Magnesia.

Health, Safety & Transportation Information for Magnesium

Safety data for Magnesium and its compounds can vary widely depending on the form. For potential hazard information, toxicity, and road, sea and air transportation limitations, such as DOT Hazard Class, DOT Number, EU Number, NFPA Health rating and RTECS Class, please see the specific material or compound referenced in the Products tab. The below information applies to elemental (metallic) Magnesium.

| Safety Data | |

|---|---|

| Signal Word | Danger |

| Hazard Statements | H250-H26 |

| Hazard Codes | F |

| Risk Codes | 11-15 |

| Safety Precautions | 43-7/8 |

| RTECS Number | OM2100000 |

| Transport Information | UN 1869 4.1/PG 3 |

| WGK Germany | nwg |

| Globally Harmonized System of Classification and Labelling (GHS) |

|

Magnesium Isotopes

Magnesium has three stable isotopes: 24Mg, 25Mg, and 26Mg.

| Nuclide | Isotopic Mass | Half-Life | Mode of Decay | Nuclear Spin | Magnetic Moment | Binding Energy (MeV) | Natural Abundance (% by atom) |

|---|---|---|---|---|---|---|---|

| 19Mg | 19.03547(27) | N/A | Unknown | 1/2-# | N/A | 107.42 | - |

| 20Mg | 20.018863(29) | 90.8(24) ms | ß+ to 20Na; ß+ + p to 19Na | 0+ | N/A | 131.34 | - |

| 21Mg | 21.011713(18) | 122(2) ms | ß+ to 21Na; ß+ + p to 20Na | (5/2,3/2)+ | N/A | 145.94 | - |

| 22Mg | 21.9995738(14) | 3.8755(12) s | EC to 22Na | 0+ | N/A | 165.2 | - |

| 23Mg | 22.9941237(14) | 11.317(11) s | EC to 23Na | 3/2+ | N/A | 177.94 | - |

| 24Mg | 23.985041700(14) | STABLE | - | 0+ | N/A | 194.4 | - |

| 25Mg | 24.98583692(3) | STABLE | - | 5/2+ | N/A | 202.48 | - |

| 26Mg | 25.982592929(30) | STABLE | - | 0+ | N/A | 213.35 | - |

| 27Mg | 26.98434059(5) | 9.458(12) min | ß- to 27Al | 1/2+ | N/A | 219.57 | - |

| 28Mg | 27.9838768(22) | 20.915(9) h | ß- to 28Al | 0+ | N/A | 228.58 | - |

| 29Mg | 28.988600(15) | 1.30(12) s | ß- to 29Al | 3/2+ | N/A | 232 | - |

| 30Mg | 29.990434(9) | 335(17) ms | ß+ to 30Al; ß+ + n to 29Al | 0+ | N/A | 238.21 | - |

| 31Mg | 30.996546(13) | 230(20) ms | ß+ to 31Al; ß+ + n to 30Al | 3/2+ | N/A | 240.7 | - |

| 32Mg | 31.998975(19) | 86(5) ms | ß+ to 32Al; ß+ + n to 31Al | 0+ | N/A | 246.92 | - |

| 33Mg | 33.005254(21) | 90.5(16) ms | ß+ to 33Al; ß+ + n to 32Al | 7/2-# | 0.536 | 248.47 | - |

| 34Mg | 34.00946(25) | 20(10) ms | ß+ to 34Al; ß+ + n to 33Al | 0+ | 0 | 252.83 | 78.99 |

| 35Mg | 35.01734(43)# | 70(40) ms | ß+ to 35Al; ß+ + n to 34Al | (7/2-)# | -0.85546 | 253.45 | 10 |

| 36Mg | 36.02300(54)# | 3.9(13) ms | ß- to 36Al | 0+ | 0 | 255.94 | 11.01 |

| 37Mg | 37.03140(97)# | 40# ms [>260 ns] | ß+ to 37Al; ß+ + n to 36Al | 7/2-# | N/A | 256.57 | - |

| 38Mg | 38.03757(54)# | 1# ms [>260 ns] | Unknown | 0+ | N/A | 259.06 | - |

| 39Mg | 39.04677(55)# | <260 ns | Unknown | 7/2-# | N/A | 258.75 | - |

| 40Mg | 40.05393(97)# | 1# ms | Unknown | 0+ | N/A | 260.31 | - |